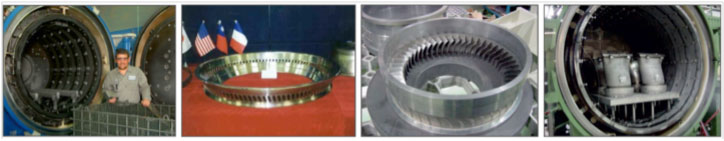

High Vacuum Heat Treat Furnaces

High Vacuum Furnaces

VP and VVP series, 2-10 bar, N2, Ar, 10-4/10-7 mbar

- Solution heat treating, annealing, stress relieving, quench hardening, degassing, tempering, homogenizing, ageing, brazing

- Vacuum carburizing FineCarb®

- Carbon steel and low alloy steels, iron base corrosion resistant steels

- Nickel and cobalt base alloy, titanium and titanium alloy, light alloy

- Other processes / applications

Advantages of VP and VVP furnaces

- Shorter cycle time, increased throughput and precise monitoring of the high vacuum process.

- Graphite or all-metal-shields heating chamber insulation, other combinations also available.

- Compact design with internal gas cooling system:

- reduces power and gas consumption

- reduces installation area

- reduces installation and start up time

- Cylindrical heating chamber enables heat treating of oversized loads.

- Light and curved graphite or molybdenum (Mola) heating elements surround the load from all sides and provides fast and uniform heating throughout the working space.

- Available with horizontal and vertical loading configuration.

- Temperature uniformity according to AMS 2750E, better than ±S°C (or ±3°C at austenitization temperature); the furnace is equipped with test ports for SAT and TUS sensors. The furnace meets SAT and TUS requirements as in accordance with AMS 2750E.

- Efficient radial cooling system with profiled gas nozzles.

- Patented convection heating system with pneumatically driven gas nozzles flaps assure smooth operation of the system even under work environment contaminated with sublimatem.

- Con Flap™ system enhances convection heating and provides for 40% time savings when heating densely packed loads in the 800°C temperature range.

- Convection heating system enables tempering of the load in one process, thus making the furnace more flexible.

- Nozzle flaps enable different cooling patterns. Depending on the load configuration, it can be quenched with gas flow from all nozzles, or directionally from top and bottom, or from sides only.

- Door locking system with a clamping ring and lip seal engineered for high pressure operation and increases door seal life time.

- High vacuum pumping system is based on mechanical (10"2 ) and oil diffusion pump (10 .. + 10"6 ) mbar pumps or optional turbomolecular / cryogenic pumps (for <10"').

- Superior quenching rate and uniform gas flow through the load up to 10 bar of cooling pressure.

- Universal furnace with wide range of applicable technologies; enables heat treatment of steel and alloys, as well as hard brazing, in accordance with SAE AMS 2769, 2759, . . . , 2773, 2801, MIL-8-99728 specification, meets requirements of the aerospace and power generation industries.

- Vacuum carburizing technology FineCarb'" also available.

- Meets European and North American safety standards.

|

|

|

Control system advantages

- Fully automated furnace operation controlled by PLC (Programmable Logic Controller) and IPC (Industrial PC-class computer).

- LCD touch screen visually displays all technological parameters of heat treatment processes.

- Large capacity of a hard disc (HDD) recording of unlimited number of recipes. It eliminates errors resulting from creating new recipes by a furnace operator.

- All process data are recorded, and can be displayed as a diagrams on a separate screen or saved on HDD or a CD.

- Export of historical data and alarm messages to external system for further analysis (e.g. to *.csv files).

- Easy integration with any date base.

- The furnace is equipped with the internal Ethernet network; Remote furnace service is available through Internet or modem connection using dedicated software.

- Optionally the control system can be equipped with advanced batch reporting and history analyzing software which can present data. using templates for standard MS Office applications, such as Word and Excel.

- A separate diagnostic screen reminds about maintenance requirements of individual components of the furnace.

- Energy efficient Power Management System to control heating and cooling capacity of the furnaces.

- SimVac simulation software supporting FineCarb® and PreNit® vacuum carburizing technologies.

- G-Quench Pro software for simulation of hardness of tool steels.

|

Technical Data

| VP horizontal | ||||||||

|---|---|---|---|---|---|---|---|---|

| 22/24 | 25/24 | 35/36 | 50/48 | 56/60 | 66/72 | 85/72 | ||

| Uniform zone (WxHxL) |

mm | 400x400x600 | 600x400x600 | 600x600x900 | 900x800x1200 900x900x1200 |

1000x1000x1500 | 1200x1200x1800 | 1500x1500x1800 |

| Max. load | kg | 200 | 400 | 600 | 1200 | 2500 | 3000 | 3500 |

| Heating power | kW | 70 | 90 | 150 | 240 330 |

375 | 420 | 540 |

| VVP-EH vertical | ||||||

|---|---|---|---|---|---|---|

| 48/48 | 60/60 | 72/72 | 88/100 | |||

| Uniform zone (WxHxL) |

mm | Ø1200x1200 | Ø1500x1500 | Ø1800x1800 | Ø2200x2500 | Other sizes and parameters available on request |

| Max. load | kg | 1500 | 2000 | 2500 | 3000 | |

| Heating power | kW | 270 | 375 | 440 | 800 | |

Vacuum Furnace Processes

Fine Carb®: Vacuum Carburizing High Pressure Gas Quench High Vacuum Furnaces PreNit: High Speed Vacuum Carburizing Vacuum Brazing: Advanced Front Loading Gas Nitriding with ZeroFLow® FURNACE/PLUS Vacuum Circuit Breaker Brazing

Specifications Subject to Change without Notice

Webinar: Gas or Oil Quenching: Which is best?

Webinar: Gas or Oil Quenching: Which is best?