SECO/VACUUM | Gas or Oil Quenching - Which is Best?

Straight Talk about Distorted Parts in Oil Vs Gas Quench

Welcome, everyone, to a webinar on not only one of my favorite subjects, but one of the most important topics in our industry, namely part distortion. Today, we will look at the factors that influence distortion and how to manage them and hopefully, at the same time, provide you with some straight talk about distorted parts.

I'd like to begin with a somewhat philosophical observation, namely that in my mind, distortion is the bane of the heat treater’s existence. It seems that distortion has plagued our industry ever since we picked up the first piece of metal and thought about how to heat it or how to cool it. And the lament that I most often hear on the shop floor is simply “Why is everybody always picking on me”? Well, this webinar will answer that question and hopefully tell us some of the things we can do about it. So, let's begin.

Here's a real world example of just what we're faced with. Our customers believe we are always at fault. That heat treating, whether it's heat treating done by commercial heaters, or heat treating done within a captive heat treater in their own heat treat department, that somehow the parts are given to us straight and flat and that we return them somehow warped and distorted. This is an example of a product that was run at a commercial heat treater who was asked to stress relieve some 304 and 316 stainless steel, laser-cut plates. The stress relief operation was conducted at 750º. So, the parts were heated slowly to 750º, soaked for two hours at temperature, and then slowly air cooled. The result is as you observe here, highly warped and distorted parts. Attempts were then made to put large heavy platens beneath and above the plates and to stress relieve them again in the hope that they would, with the weight supplied, that they would return to their original straight and flat shape. They obviously did not. At this point you might be asking yourself, “How is this the heat treater’s fault”? It's a good question. And simply put, in my mind, it isn't. The stress present in the plates was indeed relieved. And the result of this simplest of heat treat operations was significant bowing and bending of the plates. And again, the customer was confused as to why it could possibly happen. The plates were straight going into heat treatment and warped coming out of the treatment. Obviously, it had to be the fault of heat treatment, and it was not.

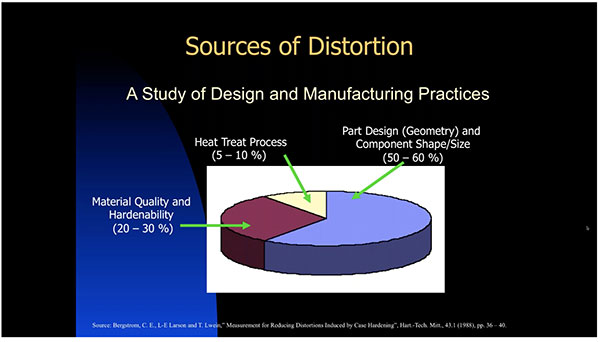

Now, over the years there have been a number of studies conducted to identify the true sources of distorted parts. Again, recall that as far as our customers are concerned, the parts were dimensionally to print when they were given to us, they were flat, they were scraped, they weren't crisp, twisted, bowed or bent. And of course, after heat treatment, they were indeed distorted and it's all the heat treater’s fault! Well, in reality, it turns out that part design, the geometry of the part – component shape and size – accounts for about 50 - 60% of the distortion, and a whopping 20 - 30% is due to material hardenability and material quality, the cleanliness of the steel, the grain size of the steel, and factors such as this. And yes, heat treatment plays its part as well. Perhaps 5 - 10% of the distortion observed after heat treatment was really the fault of the heat treatment process. I would suspect that poor fixturing, improper loading, the selection of the wrong quenchant, or a poor control of the quench media itself, are likely causes of those sources of distortion.

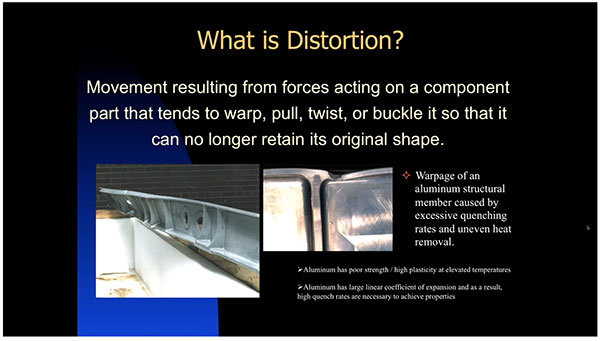

But what is distortion? Simply stated, it's movement of the parts that result in warping, pulling, twisting, bending, buckling. In other words, movement where the part can no longer retain its original shape. Here's an example of a horribly warped aluminum structural member. What occurred in this particular case was several things. First, the heat treater failed to take into account, at least in my view, the fundamental characteristics of the material. And in addition to that, the quench, the polymer quench in this particular case, the concentration was such that excessive quenching rates resulted in uneven heat removal around the surface of the part and therefore, the part bowed literally into the shape that you see.

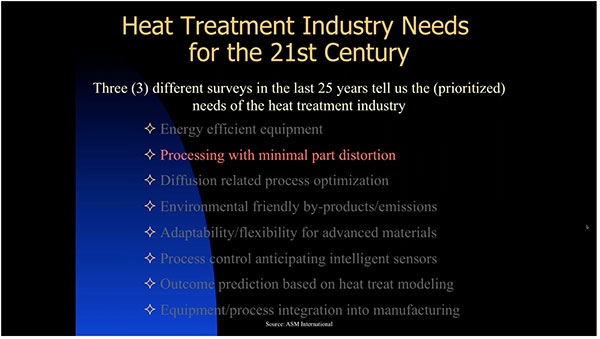

Now, over the years, a number of surveys have been conducted by industry experts (in this case, ASM International) that tell us that this is the number two issue in heat treatment. And if you'll observe this, the number one processing issue is minimizing distortion. I find it interesting that the survey doesn't talk about controlling distortion or eliminating distortion, but cuts right to the chase and talks about the heart of the matter – how we can actually minimize distortion.

To continue and view the full audio/visual presentation in its entirety, register here: https://register.gotowebinar.com/recording/4914873434159971336