Pit-LPC™ – Vacuum Carburizing Pit Furnace for Deep Case Depth on Large Parts

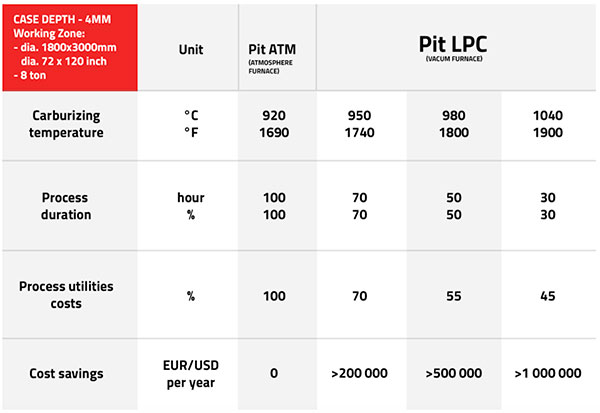

The Pit LPC is an advanced 21st century pit-type gas carburizing furnace for low pressure carburizing (LPC) of large parts or parts requiring deep case depths. As a modern alternative for atmosphere furnaces, the Pit LPC can reduce heat treating costs and improve production while improving the environment by operating in vacuum at higher temperatures than atmosphere furnaces can achieve. The Pit LPC also increases heat treater’s production throughput without purchasing additional equipment, since a single Pit-LPC furnace is equivalent to the capacity of three atmosphere furnaces, and it can be reconfigured to fit into the space of an existing atmosphere furnace. Additionally, a single vacuum furnace provides more capability since it can handle gas carburizing on larger and longer workpieces.

_450x338.jpg

)

_450x338.jpg

)

_450x338.jpg

)

_450x338.jpg)

Pit LPC is a state-of-the-art pit-type furnace solution meeting the most stringent environmental standards, while increasing worker safety through elimination of flammable and explosive atmospheres. High homogeneity of process parameters has a direct effect on the thickness of the carbonized layer and, as a result, on the quality of the processed workpieces. Plus, the unit can be reconfigured to the client’s needs; SECO/VACUUM will adapt the Pit LPC furnace so that it can be installed in the old atmosphere furnace bay.

This LPC vacuum furnace is perfect for manufacturers carburizing large or long elements such as gears, bearings, drilling tools and other elements requiring thick case depths and it is a great furnace for companies who want to increase their production capacity without purchasing additional equipment (1 Pit LPC = 3 atmosphere furnaces), or save space by replacing three machines with one that fits into the same space as one.

- Create the highest quality and uniformity in the process

The Pit LPC provides carburizing on large elements such as some larger gears, bearing races, large cutting tools and other elements requiring thick carburized layers, while providing high homogeneity of the process which has a direct quality effect on a thick carburized layer. For all workpieces, large or small, there is no intergranular oxidation (IGO) effect which provides a better appearance after processing, a quality that can enhance sales. - Reduce your production and capital costs

Another benefit is that there is minimum consumption of process gases providing reduced costs compared to standard atmosphere processing. Also, there is often less capital equipment expense: one Pit LPC equals three atmosphere furnaces so there is less floorspace needed and often lower capital cost. - Save time and increase productivity

Atmosphere furnaces require purging and atmosphere conditioning prior to start up which can slow down production. The Pit LPC provides low-pressure carburizing on an instant on-and-off basis providing better flexibility as well. Additionally, this vacuum carburizing furnace works with a quicker high-temperature process than atmosphere carburizing furnaces. - Increase work safety

Eliminate the flammable and potentially explosive gases of an atmosphere carburizing furnace since the Pit LPC uses no combustion. - Friendly to the Environment and the workforce

The Pit LPC is a cleaner process providing low-heat emission and no pollution of combustion products (CO or CO2)

Materials

- All steels used for carburizing

Industries

- Wind turbines

- Heavy machines

- Shipbuilding

- Railway

- Mining, oil & gas

- Earth Moving Equipment

- Aerospace

- Power

The Pit LPC can be easily adapted to install in the old atmosphere furnace bay

Vacuum Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow Gas Nitriding Furnace PIT-LPC™ Vacuum Carburizing Vacuum Tempering Furnace Vacuum Aluminum Brazing CVI/CVD Furnaces Super IQ®: Gas Carburizing Furnace Vacuum Furnaces for Sale

Specifications Subject to Change without Notice

Brochure: Pit-LPC

Brochure: Pit-LPC Article: LPC Pit Furnace vs. Traditional Pit Carburizing

Article: LPC Pit Furnace vs. Traditional Pit Carburizing Article: A New Solution for Low Pressure Carburizing

Article: A New Solution for Low Pressure Carburizing SECO/WARWICK is awarded a new technology patent

SECO/WARWICK is awarded a new technology patent Pit-LPC Video: How to carburize thick layers in a vacuum furnace

Pit-LPC Video: How to carburize thick layers in a vacuum furnace