UniCase Master® Reheat +4D Quench®

UniCase Master® Reheat +4D Quench®

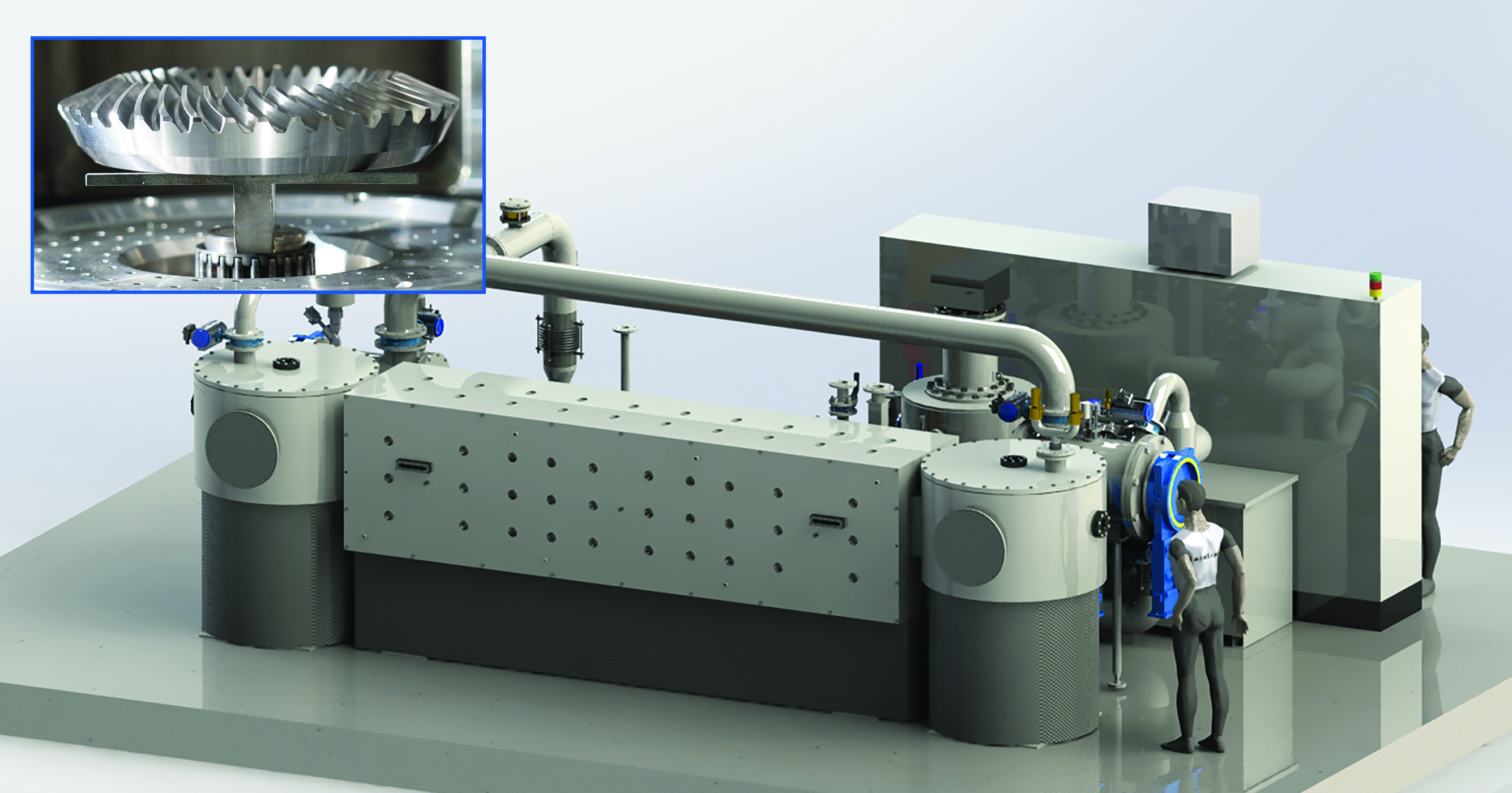

A high-volume, continuous vacuum furnace with low-pressure carburizing in a single piece flow system with precision 4D Quench®.

The Austenize & Reheat 4D Quench Reheat Furnace is a single-level design that showcases a single-piece flow vacuum heating chamber and 4D Quench chamber designed specifically for austenitizing and high-pressure gas quenching.

Benefits

- Seamlessly integrated into continuous production lines, enabling single-piece flow heat treatment.

- Capable of high-volume heat treatment for gears and power transmission components.

- Substantial enhancement of production quality and cost-effectiveness.

- Vacuum heating and vacuum material transfer to the 4D Quench chamber produces IGO-free components.

Features

- Simple in-line configuration with no need for bulky part handling, reducing the risk of part mishandling that can lead to a fall onto an oil-contaminated floor and eliminates the need for press maintenance.

- Utilizes high velocity and high pressure nitrogen gas quenching system for efficient and effective cooling.

- Features automated load and unloading to facilitate easy part transfer into the vacuum furnace and out of the 4D Quench chamber.

- Eliminates the use of quench oils, washers, and washing fluids, streamlining the overall heat treatment process while reducing its environmental impact.

Vacuum Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow

- Solo 4D Quench

- Reheat +4D Quench Furnace

- HiFlow LPC +4D Quench Furnace

- Multistage +4D Quench Furnace

Specifications Subject to Change without Notice

Brochure: UniCase Master

Brochure: UniCase Master Video: 4D Quench

Video: 4D Quench