UniCase Master® 4D Quench®

The Modern Alternative to Quench Pressing

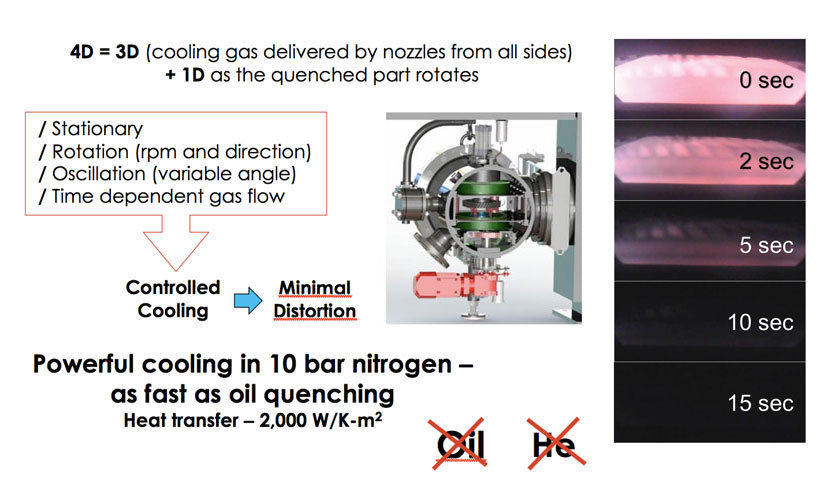

What is 4D quenching? The UniCasemaster 4D Quench is a modern alternative to press quenching. 4D quenching is a vacuum heat treatment solution for "single piece" quenching with distortion control and reduction. The SECO/WARWICK UCM® 4D Quench enables customers to replace oil quenching with "a clean" environmentally friendly, cost effective nitrogen quenching technology. The 4D Quench provides "distortion-free" alternative to oil and press quenching systems and the problems associated with their operation.

4D Quench Furnace Benefits

- Single piece flow Vacuum Heating (Through Hardening only) (see UCM page to add carburizing)

- No Oxide - vacuum clean parts.

- Simple. In-line. No bulky part handling, damage or press maintenance.

- Inline, single piece flow. 4D Quench saves money by eliminating the need for heat treatment fixtures and material logistics.

- No Oils, No Mess. No Liquids disposal. Clean.

- Parts can be conventionally carburized, slow cooled, then run through the 4D Quench System.

4D Quench was designed for those who want to significantly increase production quality and economy of high volume gears and power transmission components.

How it works

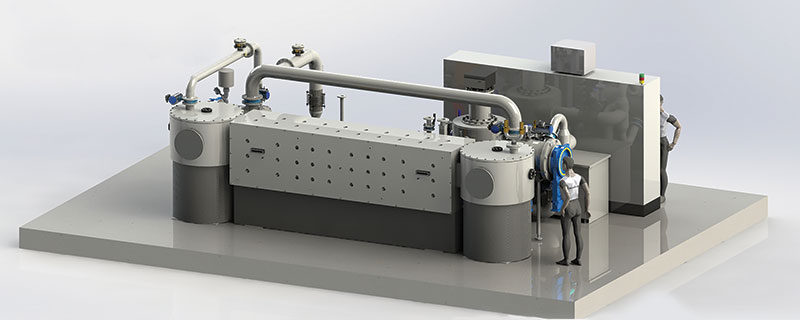

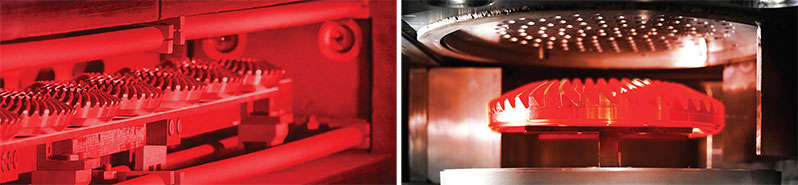

The UCM® 4D Quench® system is a unique single-piece flow vacuum furnace designed to heat or re-heat products such as gears on a single conveyor deck (see below, left). Each part is then individually transferred out of the vacuum furnace and into the quench chamber (see below, right) that uses a proprietary arrangement of cooling nozzles that surround the part (3D cooling), and the part is rotated (the 4th dimention) during quench. This quench provides a uniform flow of cooling gas from all sides; top, bottom, and sides and ensures high-speed cooling (see time lapse at lower right.)

The cooling nozzles pattern can be adequately adjusted to fit the particular parts size and shape. The entire nitrogen cooling system provides powerful and uniform quenching which results in perfect repeatability and significant reduction of distortion. Neither oil nor helium is required.

Vacuum Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow

- Solo 4D Quench

- Reheat +4D Quench Furnace

- HiFlow LPC +4D Quench Furnace

- Multistage +4D Quench Furnace

Specifications Subject to Change without Notice

Brochure: UniCase Master

Brochure: UniCase Master Video: 4D Quench

Video: 4D Quench