SECO/VACUUM ZeroFlow Gas Nitriding Webinar

Zero Flow: Gas Nitriding Technology for the 21st Century

... You may have heard about the zero flow inventor Lesyk Mazinski. He has a lifelong researcher in thermodynamics and kinetics in the nitriding of iron, it's alloys and steels. It's consulted for many different companies over the years is it the inventor of the modified Leher diagram, which incorporates nitrogen ISO concentration curves, and of course, he is the inventor of the zero flow process for gas nitriding with nitriding potential control, I've been honored to know him and call him a friend and learn from him about nitriding and a lot of his technology and knowledge is incorporated into our equipment.

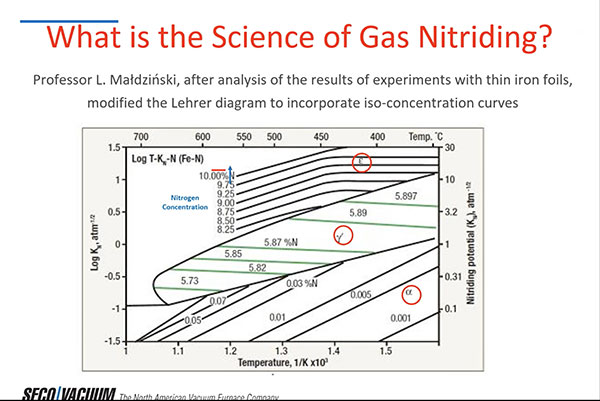

I mentioned this before, just a minute ago, the science of gas nitriding which Professor Maldzinsky put together here, these are the Leher diagram is a tool for understanding how with different nitriding potentials, it will react with the difference in the Steel's. And what he was able to do Maldzinsky was show what the nitrogen concentrations are at various temperatures, various nitride potentials and also for the different alloys. And you'll see the different curves there show the different nitrogen concentration, and you've got the different phases of the steel, you've got the epsilon phase of the white layer, the gamma prime phase of the of the white layer and what happens in the alpha in the diffusion zone of the material.

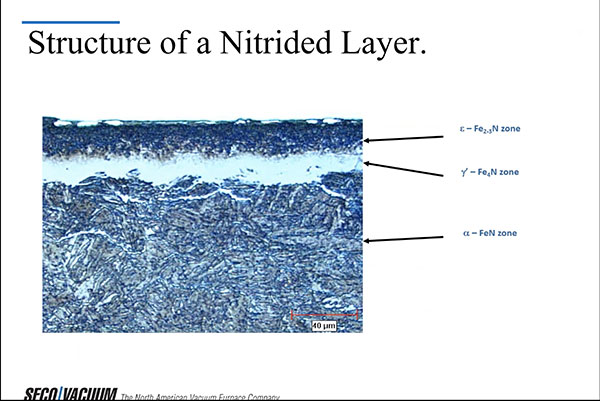

As you probably know, a, what we call the white layer is a combination of the epsilon and the gamma prime zone. And with those we show they're the iron nitrogen formulations for that. And then just straight iron nitrogen in the in the Alpha zone.

One of the things that we like to talk about here at Seco Warwick is that everything should be as simplified as far as possible, but no more. We've we think we've attributed this comment to Albert Einstein, and we think it's very sage advice.

But gas nitriding really is not that simple. It is it has evolved substantially since long before I became involved in it. But for sure in the last few years, it has evolved tremendously. Today gas nitriding can be precisely controlled. And we believe that this, our zero flow process, makes nitriding easier and much more repeatable while at the same time saving some gases. As you may be aware of, as nitriding involves many variables, you've got ammonia concentrations, temperature and the uniformity of the temperature, how exactly you're measuring the nitriding potential and how you're controlling it. All of the different measurements that come into play in any type of furnace, the surface condition of the parts are very important. The types of alloys that you're running the types of Steel's, and what alloys are actually in those parts, your retort if you're running it in the retort, etc, all of these add up to add quite a bit of complexity to the process of gas nitriding.

Why, why do we do nitriding? This is always very interesting. One of the things that I like to push over the years is to get engineers to understand that nitriding can be a process that's employed a lot more than it has in the past, and people are finding out that it has a lot of interesting capabilities, especially if you can control it, but to review some of those capabilities, you can get very high surface hardness, you can also improve wear and anti-galling properties, you can improve fatigue life of the of the component or part you can improve corrosion resistance in non stainless steels, this is a big part for nitriding that people tend to know about. And the other thing is, is that the hardness that you get will be retained at higher temperatures, whereas with through hardening and tempering or carburizing tempering, if you get up to the tempering temperature, you will start to lose your hardness. Not so, in nitriding it will go it will retain the hardness of the surface all the way up to the pretty close to the nitride temperature. In most cases with nitriding because it's a low temperature process, there is no follow up machining, any kind of differentiation and growth of the of the surface or in the in the part, stack ups or intolerances can be pretty well predicted for the part. So, the goal is to not have any hard machining, following the nitriding. In the old days, you usually ended up grinding off the white layer. Today, we can nitride a part and dial in the white layer exactly as the engineer wants it. Or we can eliminate it virtually totally.

To continue and view the full audio/visual presentation in its entirety, register here: https://register.gotowebinar.com/recording/3138251778341856514