SECO/VACUUM | IQ Gas Carburizing

Lose the Flames! Super IQ™ Smart IQ Gas Carburizing

What we'd like to talk about here is some sage advice around our theme of Albert Einstein, a very smart guy with a very high IQ, so you may understand where the smart IQ comes from. But there was something about Albert Einstein. He had a number of quotes and he was a very amusing man, and also very intelligent but he knew that everything should be as simplified as far as possible. But no more. We strive to make the complex simple here at Seco Warwick. Keeping it simple is actually much harder than one might think. I've been in the equipment business my whole life. But sometimes the equipment doesn't look like Einstein created it, but rather Rube Goldberg. Some engineers might remember that name. Equipment should be simple so it functions reliably. And Super IQ we believe is the simplification.

Now to keep it simple, it's still a struggle. To design the super IQ, we wanted to get away from theoretical gas atmosphere carburizing due to its complexity. We wanted the simplicity of vacuum through-hardening and we wanted an on-off furnace operation. In other words, no conditioning and no idling times with every one of the simplicity and quality of low pressure carburizing. To explain a little bit of this,

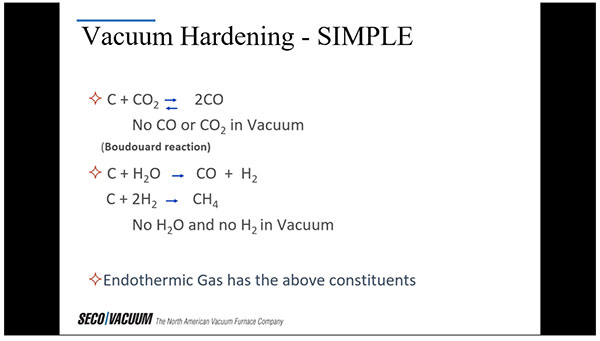

I'm going to try to stay as much away from the technical issues as possible and talk more about the equipment design. But let's take a look at why a heating chamber without any kind of gas or atmosphere can be very beneficial. And we call this heating chamber a vacuum chamber although we are still calling this a gas carburizing furnace. Gas atmospheric carburizing, as many of you may know, is not simple. In most cases, you use an endothermic gas. I'm showing here some reactions that occur in the presence of different gases whether they be CO, water vapor, hydrogen, even oxygen. A vacuum atmosphere means that in most cases you're devoid of all those gases and gas carburizing you need to get the carbon to flow into the steel. This art is well known but assuring exact results is difficult. As a good friend of mine Dan Herring says, there are over 180 reactions that are occurring which makes it not only a challenge, but fun. But we're in business and we're not here to have fun. So, we want reliable, repeatable equipment. For through-hardening, it's even more difficult. And with the gas atmosphere, you have to balance the need to not only not carburize but you also don't want to decarburize in a vacuum atmosphere. You have none of the constituents that I'm showing on this slide. You don't have CO2 or CO. You don't have water vapor. You don't have hydrogen. You don't have oxygen. Therefore, under vacuum for through-hardening, you have absolutely no decard.

So, the answer that we thought was important for the perfect gas carburizing furnace is having a vacuum or a partial pressure atmosphere and a nitrogen availability. This is again to prevent decarb to prevent IGO, your granular oxidation to save process gases, to eliminate the endogas, to use LPC or low pressure carburizing to lose the flames, something that we showed in the first picture and to provide safety.

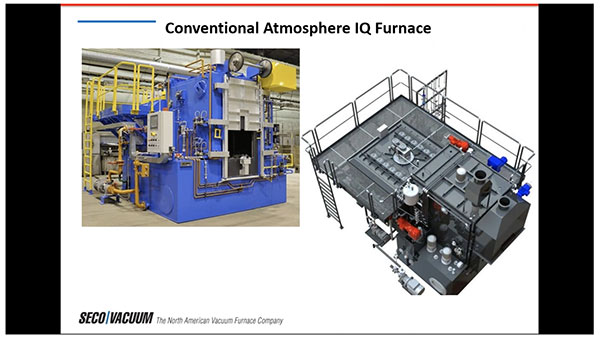

Now, you may recall a conventional atmosphere integral quench furnace from SECO/WARWICK is no different than a lot of other furnace companies out there. We have provided these for many years, a standard atmosphere integral quench furnace, all these furnaces are very similar. The quench is rather simple and the whole system operates typically in an endothermic atmosphere, which is 40% hydrogen and 20% CO. That's a generated atmosphere so you need a piece of equipment to make that atmosphere.

To continue and view the full audio/visual presentation in its entirety, register here: https://register.gotowebinar.com/recording/4123541738850865154