Heat Treatment for the Automotive Industry

Automotive applications

The automotive industry uses heat treatment to manufacture gear, wheels bearings, shafts, rings, and bushings. The most important thing for automotive heat treating is the reliability of the solutions, their efficiency, and repeatability of processes. Therefore, solutions proposed to this industry must consider the need to reduce deformations, lower process costs, shorten the cycle time, apply effective and efficient carburization, and reduce CO2 emissions.

Vacuum furnaces for the automotive industry

PARTS: gears, steering elements, fuel installation, heat exchanger, tools & dies.

TECHNOLOGY: annealing, brazing, sintering, hardening HPGQ, hardening OilQ, tempering, vacuum carburizing, vacuum nitriding, brazing aluminum, FNC ferritic nitrocarburizing, nitriding.

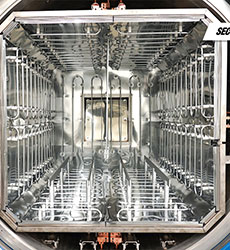

Vector® Single Chamber 2-25 Bar Gas Quench

Tool & Dies, Gears, Transmission and Fuel Components.

CaseMaster® Evolution: Multi-Chamber Oil Quench

Gears, Transmission and Fuel Components, Steering Elements.

UniCase Master® Single-Piece Flow

Gears, Transmission Components.

Gas Nitriding Furnace

Transmission and Fuel Components, Steering Elements, Tool & Dies.

VAB

Heat Exchangers.

VCB

Heat Exchangers.