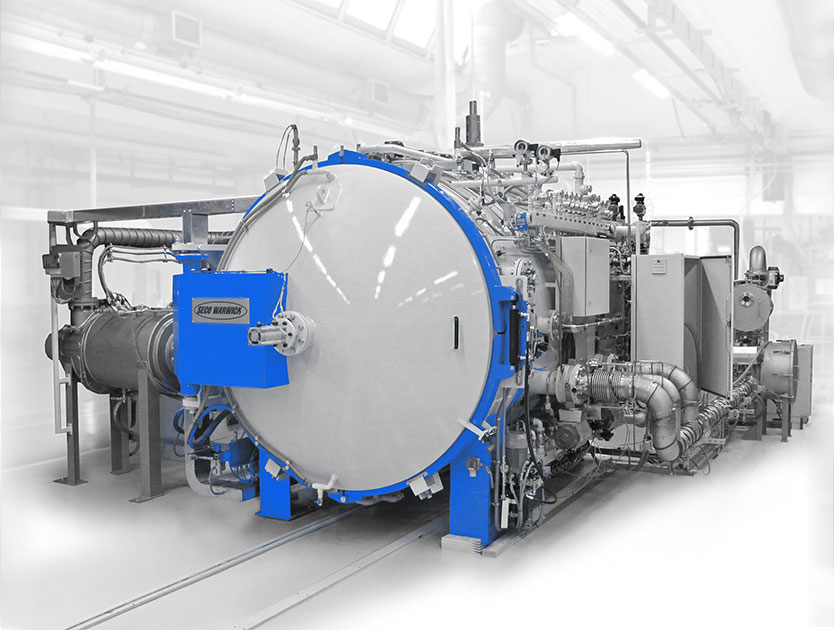

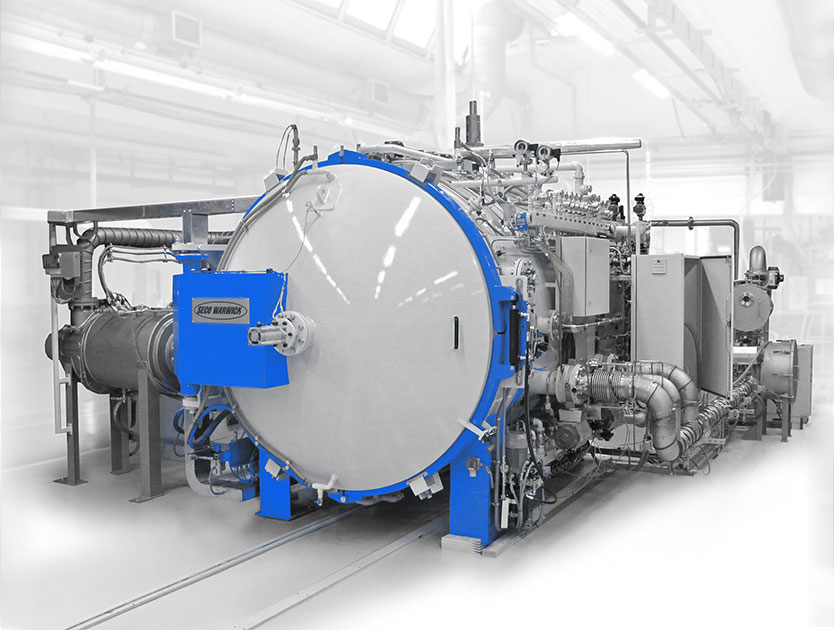

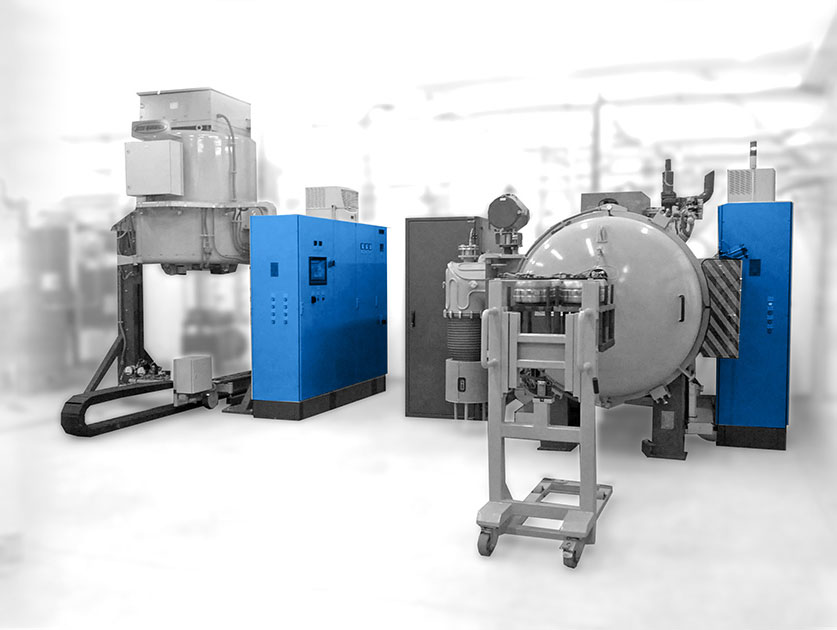

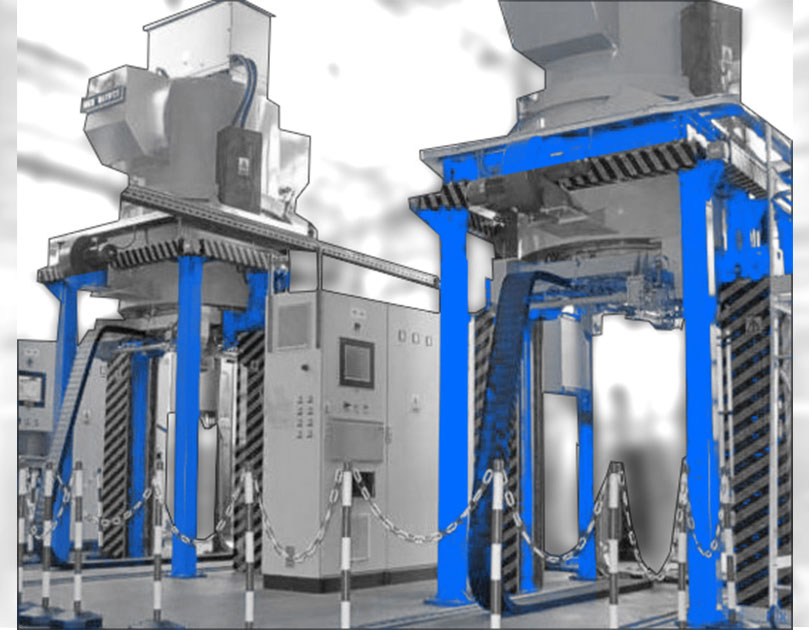

Furnace for Chemical Vapor Infiltration (CVI) and Chemical Vapor Deposition (CVD)

Process Description

CVI (Chemical Vapor Infiltration) furnaces are special solutions used in the CVI process, which is a technique for producing carbon materials by saturating them with carbon from the gas phase. They are designed to enable controlled deposition of carbon layers on porous materials.

CVD (Chemical Vapor Deposition) furnaces are special furnaces used in the CVD process, which is a technique for producing coatings through chemical reactions in the gas phase, e.g. from MTS (CH3SiCl3-Methyltrichlorosilane gas). They are designed to enable controlled deposition of materials on the surface of the processed materials.

Purification furnaces using gases such as hydrogen chloride (HCl) are used to purify graphite materials.

CVI (Chemical Vapor Infiltration), CVD (Chemical Vapor Deposition) and graphite purification devices are tools used in materials science to produce, process, and purify graphite materials.

CVI equipment consists of a reactor or reaction chamber in which chemical and temperature parameters are controlled to deposit layers of carbon on a substrate.

CVI is a process in which carbon material (usually in the form of a porous structure) is saturated or impregnated with carbon materials in the gas phase. The CVI process uses carbonaceous gases such as methane or acetylene, which react in the reactor to form carbon deposits on the substrate surface.

CVI technology is used in the production of carbon brake discs for high-performance, sports, electric and luxury cars. In the case of brake disc production, the process enables the creation of a structure with exceptional strength and low weight, which is crucial for effective braking. By precisely managing this process, brake discs produced using CVI have excellent high temperature resistance, minimal wear, and excellent friction properties, ensuring safe and efficient vehicle braking.

CVD equipment contains a reaction chamber where parameters such as temperature, pressure and chemical composition of the process gas are controlled.

CVD is a technique for producing coatings on the substrate surfaces through chemical reactions in the gas phase.

The chemical deposition manufacturing process (CVD) is a technique used, for example, to produce protective coatings (tool drilling). The CVD furnace creates protective layers on tools, increasing their durability, strength, and efficiency during processing. In the CVD process, chemical reactions allow layers to be deposited on the tool surface, improving its properties. These coatings provide better resistance to abrasion, high temperatures and corrosive environments, which translates into extended tool life and increased efficiency during industrial production.

The graphite purification process involves removing dirt and impurities from the graphite material in order to increase its purity and excellent properties.

Various techniques are used to purify graphite, including thermal treatment and chemical processes.

The graphite purification process using process gases such as fluorine and chlorine takes place in a specially designed furnace which enables the controlled removal of impurities from the graphite material through chemical reactions. During purification, graphite is subjected to high temperatures in the presence of these gases, which causes them to interact with impurities, transforming them into easily evaporated or volatile compounds.

This process is crucial for the production of high-quality graphite materials which are used in advanced technologies, such as the production of fuel cells, the electronics industry, or refractory material production. Thanks to the furnace’s use of fluorine and chlorine, it is possible to obtain pure graphite of very high-quality standards, which is extremely important in applications where the purity of the material is crucial.

CVI Process Applications

Automotive industry: Brake discs made of composite materials obtained through the CVI process are often used in the production of racing cars and other high-performance vehicles due to their lightness and strength.

Aviation and Aerospace industry: CVI products are used in the production of aircraft parts, such as structural and protective components, which must be extremely light but at the same time strong. CVI products are used to produce very low weight and durable components such as brake discs, combustion chambers and structural components in rocket engines.

Energy industry: The CVI process is used to produce components used in the energy industry such as insulating materials and nuclear reactor components.

Defense industry: CVI products are used in the production of protective elements such as battleship shields or elements of space suits.

Research and development: Materials obtained through the CVI process are used in laboratories to produce samples and components for scientific experiments, especially in fields involving high temperatures and aggressive environments.

Chemical industry: CVI products can be used in the chemical industry to produce durable components which are resistant to chemicals and high temperatures.

CVD Process Applications

Composite material production: CVD technology is used to embed ceramics in composite materials.

Electronics: CVD is used to produce thin layers on semiconductors such as silicon, which are used in the production of microprocessors, transistors, and other electronic components.

Surface protection: Protective layers such as CVD-deposited diamond layers are used to increase the abrasion and corrosion resistance of various materials.

Chemical industry: CVD is used to produce catalysts and membranes with specific chemical properties.

Aviation and Aerospace industry: CVD technology is used to produce carbon composites and other high-strength, low-weight structural materials which are used in the spacecraft and aircraft construction.

It can be used to deposit graphite layers on metal substrates for corrosion protection. These layers can be very resistant to aggressive chemical environments.

Composite material production: CVD technology is used to embed ceramics in composite materials.

Purification

Graphite materials purification is the process of purifying and removing impurities from graphite or graphite materials in order to obtain products of high purity and specific properties. The applications for graphite material purification include:

Electronics: In the electronics industry, pure graphite is used in the production of electrodes, injection electrodes, electron tube electrodes and battery electrodes. Graphite purification allows users to obtain materials with high electrical and thermal conductivity, which is important in many electronic applications.

Chemical industry: Pure graphite is used in the production of catalysts, electrolysis electrodes, chemical reactors, and components in chemical processes, so it is important to get rid of impurities which could interfere with chemical processes.

Metallurgical industry: Graphite is used in metallurgical processes, for example steel production, to obtain both high temperatures and reduce metal oxides. The graphite purity is important to avoid contamination in metallurgical processes.

Energy industry: In thermal power plants and nuclear reactors, graphite is used as a moderator or neutron moderator material. Graphite high purity is crucial in these applications.

Scientific research: In scientific research, especially in fields related to solid state physics, chemistry and nanotechnology, pure graphite is used to produce samples and laboratory equipment. Purification of graphite materials is essential to obtain accurate experimental results.

Aviation and Aerospace industry: Graphite is used in the production of structural elements such as housing elements and supporting structures in spacecraft and airplanes. The high purity of graphite helps maintain the strength and lightness of these elements.

Purification of graphite materials is important because impurities can affect the material’s properties and performance in various applications. Purification processes can include various methods such as chemical processes, heat treatment and mechanical treatment to obtain the graphite material’s desired properties.

Vacuum Heat Treat Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow Gas Nitriding Furnace PIT-LPC™ Vacuum Carburizing Vacuum Tempering Furnace Vacuum Aluminum Brazing Vacuum Brazing Furnace CVI/CVD Furnaces Super IQ®: Gas Carburizing Furnace

Specifications Subject to Change without Notice