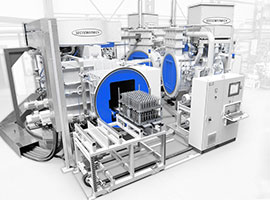

Custom engineered systems to support many process types

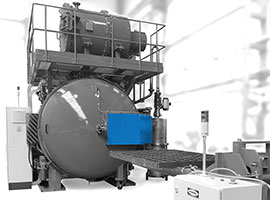

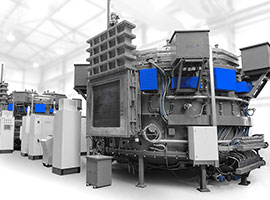

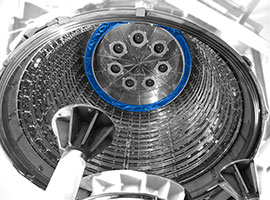

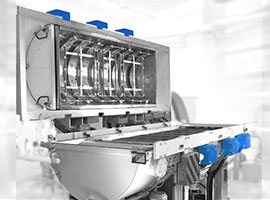

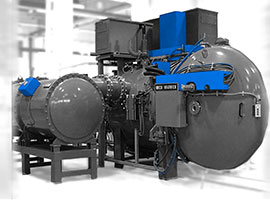

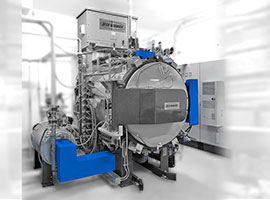

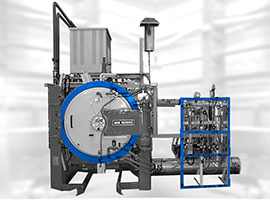

Custom Vacuum Furnaces Designed for Your Application

If you are looking for customized vacuum solutions, SECO/VACUUM’s custom designed furnaces are a great choice.

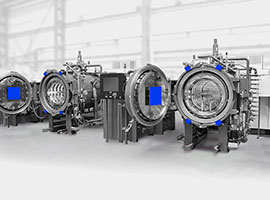

SECO/VACUUM can create a custom designed vacuum furnace for you because:

- We have dozens of years of experience

- Thousands of deployed solutions have been made

- An international team of engineers with various specialties is available

- We work with universities at home and abroad

- There are proven technologies and dozens of patents which allow us to go far beyond the engineering of standard products and standard manufacturers.

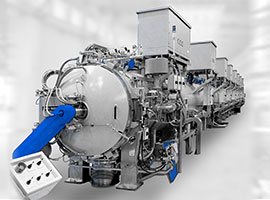

Vacuum Heat Treat Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow Gas Nitriding Furnace PIT-LPC™ Vacuum Carburizing Vacuum Tempering Furnace Vacuum Aluminum Brazing Vacuum Brazing Furnace CVI/CVD Furnaces Super IQ®: Gas Carburizing Furnace

Specifications Subject to Change without Notice