FineCarb®: Vacuum Carburizing

FineCarb® Vacuum Furnace Carburizing Heat Treatment

FineCarb® is an advanced low-pressure carburizing process used in SECO/WARWICK’s gas or oil quench furnaces providing highest repeatability and uniformity. It was developed in cooperation between SECO/WARWICK S.A and Technical University of Lodz in Poland. The underlying physical model of carbon transfer is based on the idea of the intermediate carbon deposit and the "extended boost – diffusion" schedule in combination with the expert software system SimVac PlusTM.

Low Pressure Carburizing (Vacuum Carburizing) with FineCarb®

SECO/VACUUM has various furnaces that utilize SECO/WARWICK’s Proprietary FineCarb® process and software, known as SimVac®. The following furnaces all can have FineCarb® LPC added as a feature:

- Vector® (hyperlink) Standard Vacuum Furnaces with up to 15 Bar HPGQ

- CaseMaster® Evolution (CMe) Vacuum Oil Quench Furnaces.

- Super IQ Gas Carburizing Furnace.

- Uni-CaseMaster® Single Piece Flow Vacuum Furnace.

- Vector CMe “The Works for Aerospace” – combination oil and high pressure gas quench vacuum furnace.

Vacuum carburizing (Low Pressure Carburizing – LPC) is known to reduce IGO (intergranular oxidation) and also to reduce distortions during quenching versus old fashioned atmosphere gas carburizing. The SECO/VACUUM FineCarb® process assures manufacturers of the highest carburizing quality and repeatability.

Carburizing with FineCarb® – low pressure carburizing technology

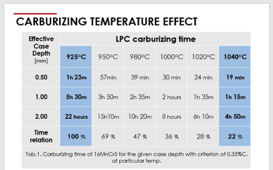

Low pressure carburizing is characterized by an extraordinarily high coefficient of carbon transfer. In the initial phase of carburizing, for example, at 950°C (1740°F), the carbon stream directed at the workpiece surface reaches the rate of 250 g/m2h. This means that, in the case of thin carburization layers, the process is considerably faster than the conventional gas carburizing process. It also means that you need software to help harness the advantages of low pressure carburizing. The SVT FineCarb process uses SECO/WARWICK’s proprietary SimVac simulation software to help establish cycles for the desired case depths and properties.

Advantages

- Guaranteed carburizing repeatability and uniformity of the case depth from O.1 mm to 5 mm

- Highly efficient use of the carburizing gas

- No soot. No tar.

- Carburizing gas flow based on workload size

- Reduced cycle time by increasing carburizing temperatures with no equipment damage (see Pre-NitLPC® for more information)

Added Features

- Excellent uniformity and repeatability

- No CO2 emissions, Environmentally-friendly

- Excellent carbon penetration when carburizing densely packed loads & complex shaped workpieces or blind holes (diesel engine nozzles)

- Better quality thanks to no intergranular oxidation (No IGO) & precise case uniformity

SECO/VAUUM Furnaces that use FineCarb®:

Vector 15 & 20 bar, CMe Oil Quench, Super IQ, CMe 25 bar HPGQ

Vector HPGC |

Super IQ |

Vector CMe |

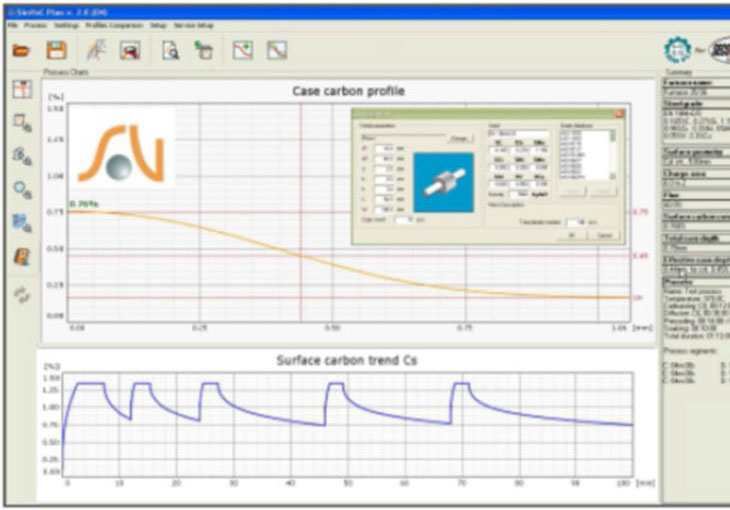

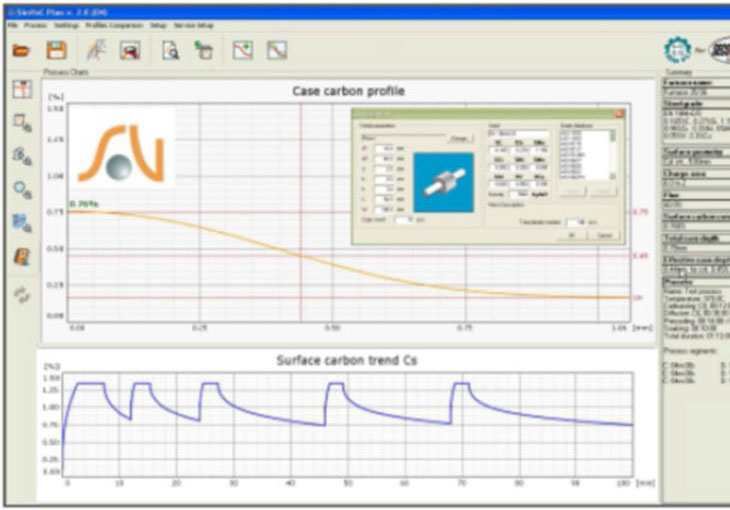

SimVac™ – Carburizing Simulator

Vacuum carburizing requires a better understanding of the parts, surface area and temperature. Due to the more complex process of LPC, a good simulation package is a must to establish the correct carburizing cycle to establish flow rates of carburizing gases and timings of boost and diffuse segments. SimVac is this tool.

Advantages

- Optimal planning for segments of carburizing process, divided into: carburizing and diffusion stages

- Calculations based on steel grade, size and shape of parts as well as cooling profile for hardening

- Automatic or manual simulation operation mode

- Simulated carbon profile comparison

- Intuitive graphical interface

- Integrated with SecoVac – furnace control system

|

|

Vacuum Furnace Processes

Fine Carb®: Vacuum Carburizing High Pressure Gas Quench High Vacuum Furnaces PreNit: High Speed Vacuum Carburizing Vacuum Brazing: Advanced Front Loading Gas Nitriding with ZeroFLow® SECO/PREDICTIVE SECO/PREVENTIVE

Specifications Subject to Change without Notice